Indian Steel Industry: A Global Powerhouse

The Indian steel industry demonstrates resilience, innovation, and quality commitment in the global market.

Transformational Growth: Meeting Global Demand

Indian steel manufacturers adeptly convert challenges into opportunities, contributing significantly to global steel supply.

Factors Driving Success: Innovation and Expansion

Modern technologies, efficient processes, and adherence to international quality standards bolster India’s steel sector.

Global Impact: Driving Economic Development

Indian steel plays a pivotal role in global infrastructure projects, fueling economic growth worldwide.

Historical Perspective: A Legacy of Innovation and Growth

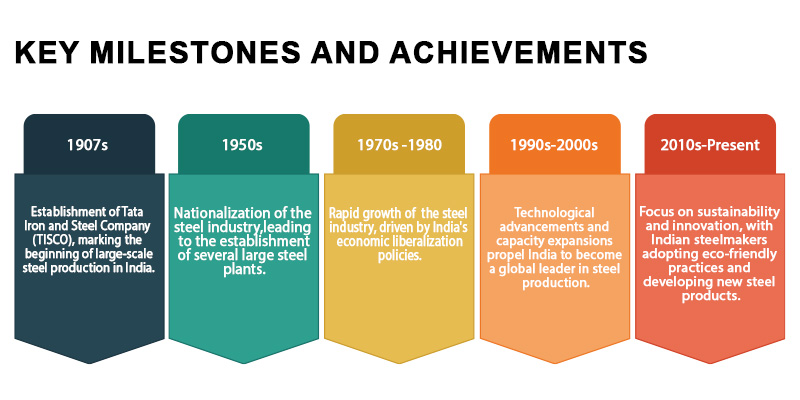

India’s steel industry began with TISCO in 1907, ushering large-scale production. This ignited industrialization, shaping India’s economic landscape.This moment sparked industrialization, shaping India’s steel industry, pivotal for economic development.In its infancy, steel focused on domestic needs, but expanded with India’s growing economy, modernizing production.

In the 1950s, the public sector steel industry was established, creating major plants like HSL and SAIL. These plants played a vital role in meeting India’s post-independence steel demand.

Global Impact: A Rising Star in the World Steel Market

In recent decades, India’s steel industry has surged, becoming a global leader due to key factors:

Technological Investment: Indian steelmakers adopt advanced automation and manufacturing techniques, ensuring high-quality products.

Capacity Expansion: Expanding production capacities strengthens India’s role as a major global steel supplier.

Quality Assurance: Stringent quality control measures bolster trust among global consumers.

Cost Efficiency: Indian steel maintains competitive production costs, enhancing global market success.

Diversification: Steelmakers broaden product range, capturing new markets and higher margins.

Global Partnerships: Pursuing partnerships and acquisitions abroad expands reach and technological access.

Challenges and Opportunities: Embracing Sustainability and Addressing Environmental Concerns

While the Indian steel industry has made remarkable strides, challenges remain, including environmental concerns and raw material availability. However, these challenges also present opportunities for innovation and sustainable practices.The industry is adopting cleaner technologies, diversifying raw materials, and embracing sustainable practices to boost global competitiveness.

Sustainable Practices: Leading the Way in Eco-Friendly Steel Production

This involves adopting energy-efficient methods, investing in waste recycling, and reducing the carbon footprint, bolstering the industry’s eco-friendly image and global standing.

Energy Efficiency:

- Adopting advanced technologies and processes: Indian steelmakers are replacing outdated equipment with more energy-efficient technologies, such as high-efficiency motors, variable speed drives, and heat recovery systems. These upgrades help to reduce energy consumption and associated greenhouse gas emissions.

- Optimizing production processes: Steel manufacturers are implementing lean manufacturing practices and process optimization techniques to minimize energy usage throughout the production cycle. This includes optimizing furnace operations, reducing downtime, and improving waste heat recovery.

- Promoting renewable energy integration: Indian steel companies are exploring ways to integrate renewable energy sources, such as solar and wind power, into their operations. This shift towards cleaner energy sources helps to reduce reliance on fossil fuels and further reduce the industry’s carbon footprint.

Waste Recycling and Circular Economy:

- Maximizing material recovery: Steelmakers are implementing comprehensive waste management strategies to maximize material recovery and minimize waste disposal. This includes segregating waste streams, investing in advanced sorting technologies, and establishing partnerships with waste recycling companies.

- Promoting slag utilization: Steel slag, a byproduct of steelmaking, is often discarded as waste. However, it has potential applications in construction materials, road paving, and cement manufacturing. Indian steel companies are promoting the utilization of slag, reducing waste disposal and creating a more circular economy.

- Developing closed-loop recycling processes: Steel manufacturers are exploring closed-loop recycling processes, where steel scrap is directly converted back into new steel products without the need for additional raw materials. This approach significantly reduces the environmental impact of steel production.

Carbon Footprint Reduction:

- Adopting carbon capture and storage (CCS) technologies: CCS technologies capture carbon dioxide emissions from steelmaking processes and store them underground, preventing them from entering the atmosphere. Indian steel companies are investing in CCS research and development to implement these technologies in the future.

- Exploring alternative fuels and processes: Steelmakers are exploring the use of alternative fuels, such as hydrogen and biomass, in their operations. These alternative fuels can significantly reduce carbon emissions compared to traditional fossil fuels.

- Promoting sustainable procurement practices: Indian steel companies are adopting sustainable procurement practices, sourcing raw materials from suppliers that adhere to environmental and social responsibility standards. This approach helps to reduce the environmental impact of the entire supply chain.

By embracing these sustainable practices, the Indian steel industry is playing a crucial role in addressing environmental concerns and contributing to a more sustainable future. The industry’s commitment to eco-friendly practices not only enhances its environmental performance but also strengthens its global competitiveness and reputation. As the world transitions towards a low-carbon economy, India’s steel industry is well-positioned to lead the way in sustainable steel production.