At Unispares India, we conform to international standards for production management. We possess best-in-class facilities for a complete product development cycle, utilizing world-class CNC and conventional machines for precise tolerances and excellent finishing.

Our operations are managed by a team of highly skilled employees from diverse disciplines. With a forging plant occupying 10,000 square meters, we cater to all your standard or special part needs under one roof.

Read MoreWe are committed to product upgrades and innovation to provide maximum efficiency.

We give utmost importance to product quality and strictly control all critical aspects.

If you have questions or any details to communicate with us, please do not hesitate to contact us.

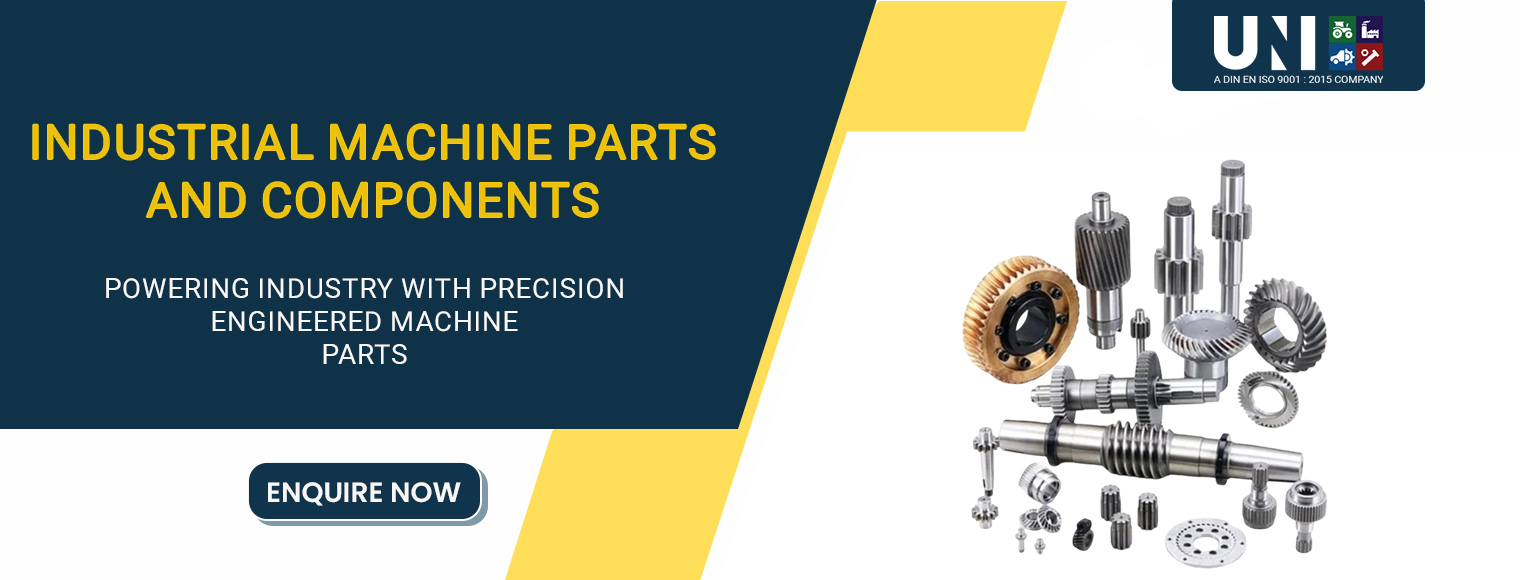

Precision machining is a critical process that removes excess raw material to create components with close tolerance finishes. At Unispares India, we ensure every part meets rigorous industry standards.

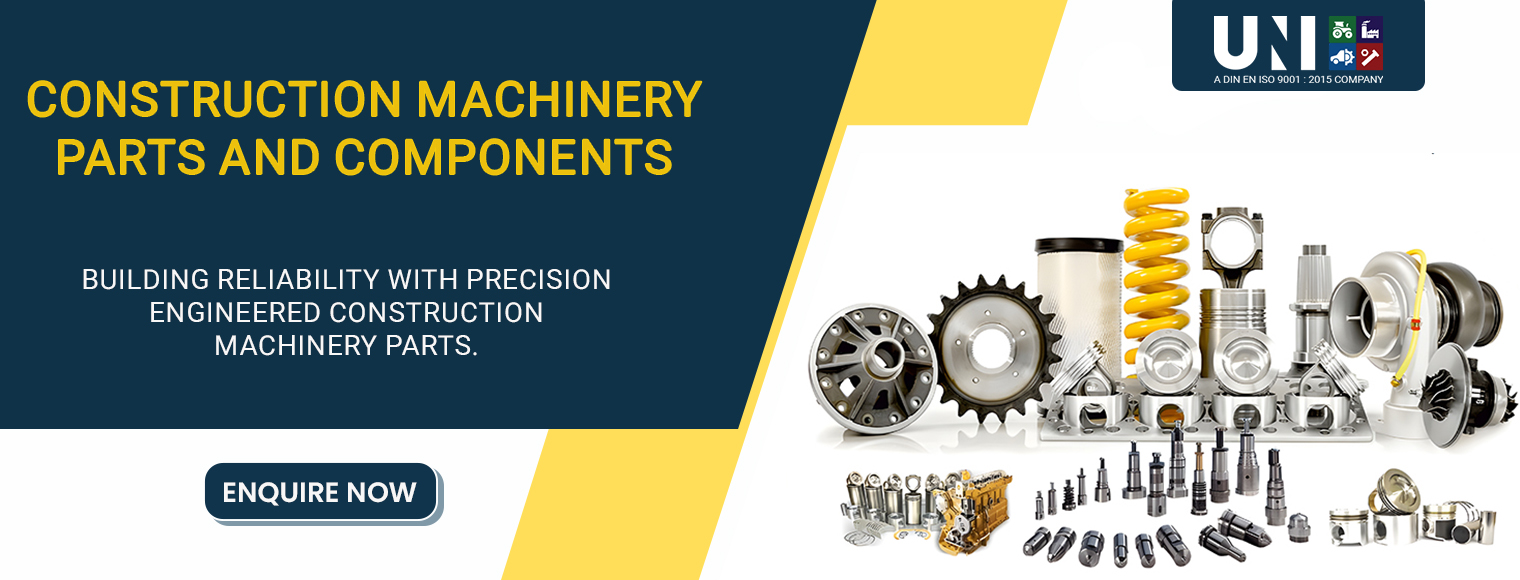

We specialize in manufacturing high-quality parts for agricultural, construction, and automotive machinery. Our solutions cater to a wide range of applications, including tractors, harvesters, cultivators, and heavy machinery.

One of the biggest reasons to choose us is our commitment to every client. Whether you require small prototypes or large-scale production, we apply the same precision and methodology. With complete in-house facilities, we offer a "one-roof" solution for efficient manufacturing.

To OEMs & Tier 1 companies in Germany, Hungary & Netherlands.

Growing presence in USA, Ireland, and Canada.

With a strategic focus on the European market, we have strengthened our position by offering a flexible approach that caters to any order size. We are continuously committed to product upgrades and innovations to provide maximum efficiency.

Partner With Us

Unispares India powers industries worldwide with top-quality machinery components. From high-performance tractor parts to durable construction machinery components, we engineer excellence.