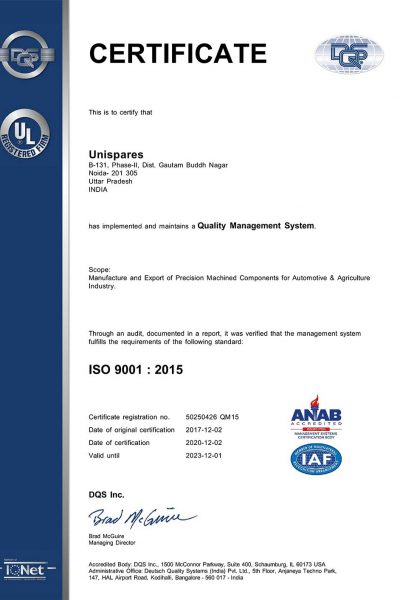

We believe it’s important to achieve excellence in the manufacturing of specific parts for the agricultural, automotive, construction, and industrial machinery. And to provide our client the best and always perfect up to the specifications we often continuously keep adding and improving our quality control procedures and parameters. We have a dedicated team for carrying out quality improvement in totality. We have also been certified with ISO 9001:2015 by UL DQS for our standard and best quality management system which is at par with global standards.

We have a skilled dedicated team for quality management process, where they audit the products to ensure that only international standards products are shipped out. Also, we constantly upgrade quality management systems as per the latest specification and newest equipment in the international market. Strict quality control measures are followed at every stage of the production procedure. It begins when the raw material is bought and ends when the finished product is shipped. In every important stage, the product has to go through the quality control procedure under-skilled team and pass it. We already have ISO 9001. And we are following ISO 14000 standards also. Understanding the present requirement in the market we also additionally follow formats like PPAP, AP&P, SPC, MSA, FMEA and also trying to get our TS Certification at the earliest.

Unispares India understand the latest requirement and hence are following the formats like PPAP, AP&P, SPC, MSA, FMEA, and trying to obtain our TS certification in addition to our ISO 9001 : 2015 certification. Our quality products have to pass through the whole quality assurance process before it is shipped to you for your use. You can see our certification for ISO 9001 : 2015, as these are the standard that we maintain during our manufacturing to maintain consistency, expected quality levels on all items we produce. Our QA is one of our non-separable processes and ensures the absence of unexpected defects. Quality assurance is a way that we as manufacturers manage our product quality.

With adherence to international standards, efficient services and a team of trained personnel, we produce high-quality steel and stainless steel forged and machined parts.

Certified with ISO 9001 for maintaining a quality management system at par with international standards.

Management System Latest and hi-tech quality system ensures highquality from material procurement to consignment dispatch.

Advanced equipment and methods like PPAP, SPC, AP&P, MSA, FMEA, etc are used for quality testing.

Regular training sessions are conducted to increase team efficiency and enhance skills for conscious quality innovation.

With regular training sessions and awareness, the staff is well versed with new production techniques and management.

The use of CMM facilitates 3D inspection with accuracy and repeatability up to 1 Micron.

At Unispares India, we are known for delivering quality parts and components to our clients that meet their exact specifications. We have the loyalty of our customers for one main reason that for us the requirement and timeline of our clients come first. To achieve this we pursue and have a continuous quality system. Whenever you are talking about our engineering, quality of our products, and précised process that we follow, all that will keep highlighting is the quality and controlled environment. With the continuous upgrade in methods and training of our team members, we ensure that you will always receive the best and up-to-date service. We have an audit system to ensure the best international standards are maintained.

We have also installed Coordinates Measuring Machine, CMM which has the capacity to perform a 3D inspection for advanced level accuracy and repeatability up to 1 Micron. The instruments like computerized R&R (repeatability and reproducibility) make errorless product manufacturing. The products are especially and strictly measured for their desired specifications and tolerance so that there is no place for any inaccuracy.

Many parts that we supply to our clients are used in hydraulic cylinders assemblies and are high precision parts. These parts are used in high-pressure conditions and interference fits, hence surface roughness testing is very crucial for its performance. So we make sure that the parts are exactly according to specifications and in perfect condition to support their role. This quality control is carried out with SRT instruments like Mitutoyo, Japan.

Heat treatment being one of our key operations makes our parts more reliable, durable, and with high strengths. We offer heat treatment services like Toughening Case Hardening Through / Full Hardening Indication Hardening, etc.